- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Metal Working

Previous

Next

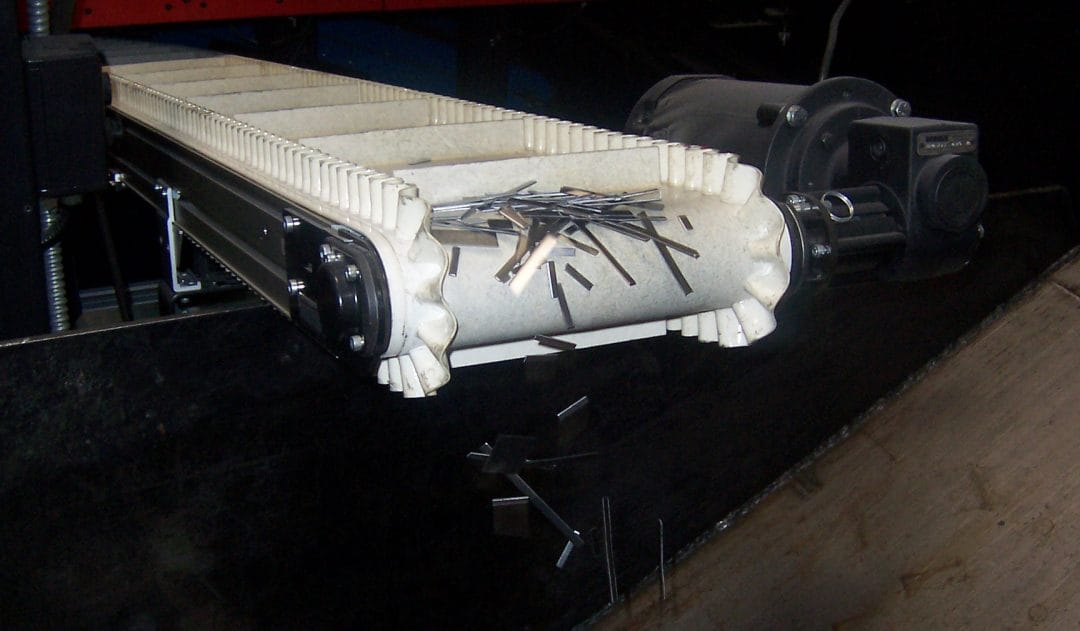

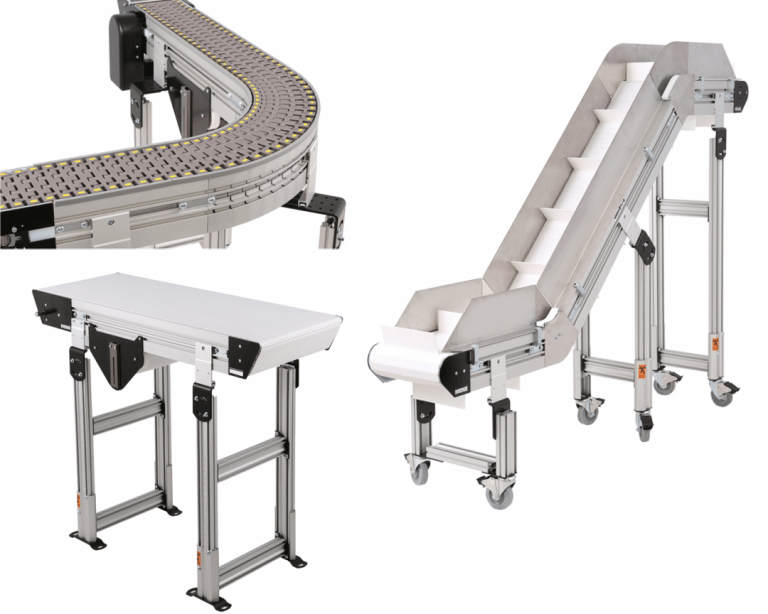

Low Profile Metal Working Conveyor Systems

2200 Series Industrial Conveyors:

Dorner’s 2200 series conveyors offer:

- Boxed frame of extruded aluminum prevents frame racking and adds strength

- Stainless steel bed plate for added durability on belted conveyors

- Low profile, space saving designs

- Fully enclosed bearing for protection from the harsh environments

- T-Slots allow customers to mount any guiding or accessories that they might need in their conveyor systems

- Modular metal working belt and open frame design for cooling and draining

Modular Plastic Belt Series Industrial Conveyor

At times, sharp edges on metal parts or scrap can damage urethane belts or drainage for machine coolants is needed. Dorner offers a full line of plastic chain conveyors that resists cutting and allows drainage of coolants and oils. This line of conveyors is based on the 2200 series box frame style design and can more than double belt life, therefore reducing maintenance time and the total cost of ownership.

Metal Working Conveyors: Delivery

Dorner has designed and engineered the widest selection of guiding, stands, gang drives, common drives, motion sensors, controls and other common accessories that effectively automate metal operations in the industry. With unmatched lead times of 5 days, Dorner can deliver the 2200 series conveyors with customer selected options faster than any other company in the industry. When next week is too late, call Dorner today!

Conveyors Metal Working

2200 Belted Conveyors

- Small Part Transfers

- Part Accumulation

- Precision Part Movement

- Small Part Handling and Positioning

- Part/Package Infeed and Outfeed

- Automated and Manual Assembly

2200 Modular Belt Conveyors

- Ladder-style, open frame construction for water and chemical drainage and air cooling.

- All belts fully contained in UHMW guiding for maintenance free tracking.

- Universal T-slot for ease and flexibility of adding accessories using industry available hardware.

- Additional frame widths and expanded guiding and chain options.

- Consolidated motor & control offerings.

2700 Medium Duty Conveyors

Featuring an increased weight rating and extended maximum width, the 2700 Series Medium Duty is designed for medium load conveyance in material handling and eCommerce applications. This conveyor includes v-guiding and precision belt tracking to eliminate belt sway even when the conveyor is wider than it is long.

The lightweight aluminum frame design makes the 2700 ideal for AGV/AMR applications and can carry a heavier payload without weighing down the robot. The increased width and low profile mounting also allow this conveyor to fit into smaller spaces while maintaining the strength needed to convey larger products.

DCMove Belted Conveyor

The DCMove Belted Conveyor features an economic painted steel frame with options for a variety of fabric or rubber belting. This new conveyor system is also built with an internally mounted motor within the tails, further reducing the conveyor’s footprint and providing an easy-to-integrate conveyor package. With a sleek, flush-sides design, the DCMove easily fits into tight spaces and maximizes belt coverage.

In combination with Dorner’s v-guided belt tracking and precise rack and pinion belt tensioning, the features of the DCMove Belted Conveyor will better serve the logistics, e-commerce, and material handling industries.

3200 Belted Conveyors

- Parts Transfers

- Part Accumulation

- Precision Part Movement

- Part Incline / Decline Routing

- Part Handling and Positioning

- Automated and Manual Assembly

3200 Modular Belt Conveyors

- Flush tail design locates bearing inside frame to fit in tight spaces

- All belts fully contained in UHMW guiding for maintenance free tracking

- Patented sprocket alignment key for worry free belt maintenance

- Dual t-slot or patented Smart Slots® for flexibility and clean sided applications

- Inboard type frame connection joint improves strength while keeping t-slots open

- Stand mounts lock in into the frame for strength and durability, yet movable anywhere along frame length

- Optional integrated power transfers for small part handling

- Flexible belt containment system allows for tab or bearing retention method for up to 4 corner modules

3200 Precision Move Conveyors

- High load capacity urethane belting with kevlar cords (True Timing Belt)

- No capacity drop when pushing belt

- All widths feature a single belt for increased mounting flexibility

- Positive drive no slip belting and side guides provide worry free belt tracking

- Use optional cleats to create pockets for controlled part flow

- Minimum pallet mounting bar is spacing 1” in length

- T-slots make mounting accessories simple with no drilling or special tools

- Compatible with standard drive packages

- Available with servo motor and mounts for increased accuracy of index

- Servo package includes fully integrated solution with intuitive PC interface

- Sealed ball bearings

Dorner — Asia

Dorner (M) SDN. BHD.

128 Jalan Permatang Damar Laut, Bayan Lepas 11960

Penang, Malaysia

Products

Menu

Industries

Menu

Quick Links

Menu

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy